Fatigue Testing Machine

Fatigue Testing Machine Specification

- Power

- 100 Watt (w)

- Response Time

- < 1 s

- Features

- Robust build, easy specimen mounting, repeatable testing

- Humidity

- Relative, up to 85% non-condensing

- Automation Grade

- Semi-Automatic

- Mounting Type

- Floor mounted

- Number of Specimens

- Up to 2 specimens per cycle

- Accuracy

- 1%

- Port Size

- Standard M12

- Equipment Type

- Fatigue Testing Machine

- Display Type

- Digital LED Display

- Specimen Size

- Standard 100 mm x 25 mm

- Frequency

- 50 Hz

- Product Type

- Fatigue Testing Machine

- Dimension (L*W*H)

- Blue and White

- Max Height

- 1450 mm

- Operating Voltage

- 220 V

- Voltage

- 220 Volt (v)

- Measuring Range

- 0-1000 N

- Hardness

- Steel construction (HRC 35-45)

- Application

- Metal, Rubber, and Polymer Fatigue Testing

- Interface Type

- RS232/USB

- Resolution

- 0.01 N

- Weight

- 750 Kilograms (kg)

- Test Range

- 0-10 KN

- Gas Pressure

- Not applicable (generally operates electrically)

- Power Supply

- 220V AC, 50 Hz

- Temperature

- Ambient, 10C to 35C

- Usage

- Industrial Lab Test

- Capacity

- 100 kg

- Machine Weight

- 750 kg

- Test Speed

- Adjustable, typically up to 1800 rpm

- Test Width

- Standard width 30 mm

- Test Stroke

- Up to 100 mm

- Control Mode

- Automatic digital control

- Safety Features

- Emergency stop, overload protection

- Compliance

- IS/ASTM/ISO Standards

- Product Color

- Blue and White

- Cycle Counter

- Digital, up to 9,999,999 cycles

- Operation

- Electric motor driven

- Finish

- Powder Coated

- Ambient Noise Level

- < 70 dB

- Frame Material

- Heavy Duty Steel

Fatigue Testing Machine Trade Information

- Minimum Order Quantity

- 10 Units

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Box.

- Main Export Market(s)

- Australia, Eastern Europe, Central America, Africa, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

About Fatigue Testing Machine

Elite Fatigue Testing Machine: Competitive Advantages & Versatile Applications

The Fatigue Testing Machine stands out for its robust build, precision, and repeatability. Its competitive advantages include unmatchable accuracy (1%), automatic digital controls, and a superlative digital cycle counter. Suited for metal, rubber, and polymer fatigue tests, it supports up to two specimens per cycle. With its adaptable test speed and sturdy frame, it elevates testing standards for researchers, manufacturers, and industrial labs seeking reliable data across diversified materials.

Certifications, Sample Availability, & Logistics for Fatigue Testing Machines

Proposal amounts and order processing for our certified fatigue testing machine are streamlined for efficiency. Each unit complies with IS/ASTM/ISO norms, assuring elite quality. Samples can be requested to evaluate performance. Transport services from India operate via standard FOB port terms, ensuring timely and secure delivery to your location. Whether you're a distributor or supplier, our expert team facilitates seamless commissioning and support throughout the order and logistical process.

FAQ's of Fatigue Testing Machine:

Q: How does the emergency stop and overload protection enhance user safety in this fatigue testing machine?

A: The emergency stop and overload protection features are designed to immediately halt operations and prevent machine damage or user injury, ensuring safe, controlled testing environments.Q: What materials can be tested using this fatigue testing machine?

A: This machine is suitable for evaluating the fatigue resistance of metals, rubbers, and polymers, providing accurate measurements for a wide range of industrial applications.Q: When should periodic maintenance be performed for optimal machine performance?

A: Periodic maintenance is recommended after every major testing campaign or at scheduled intervals specified in the manual to sustain unmatchable accuracy and longevity of the machine.Q: Where is the machine typically mounted for optimal stability and operation?

A: The Fatigue Testing Machine is floor mounted to ensure maximum rigidity and stability during operation, suitable for industrial laboratory environments.Q: What process ensures precise measurement and repeatability during specimen testing?

A: Automatic digital controls and robust mounting procedures guarantee precise measurements and highly repeatable results for every fatigue test conducted.Q: How is specimen data recorded and monitored during testing?

A: Specimen data is captured and displayed on the digital LED display, with options for data export via RS232/USB interfaces for further analysis and documentation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory and Scientific Equipment Category

Variable Rectangular Slit

Minimum Order Quantity : 10 Units

Material : Steel

Color : Black and Silverq

Application : Optical and photonic beam shaping

Control Mode : Manual

Product Type : Variable Rectangular Slit

maxscope

Minimum Order Quantity : 10 Units

Material : Plastic And Metal

Color : Multicolor

Application : In Labs

Control Mode : Manual

Product Type : Maxscope

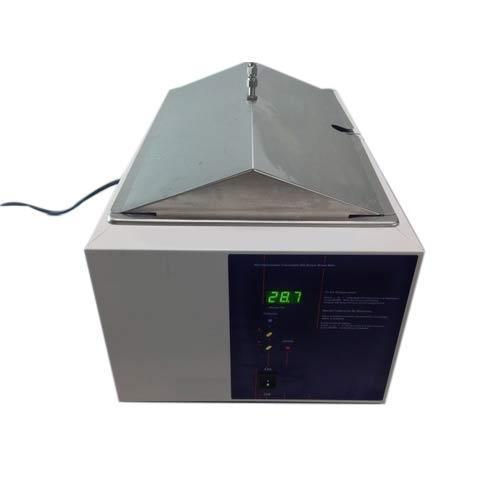

Temperature & Precision Control Water Bath

Minimum Order Quantity : 10 Units

Material : Metal

Color : Silver And Blue

Application : Heating and maintaining water temperature for laboratory use

Control Mode : Digital PID Temperature Controller

Product Type : Precision Control Water Bath

Bronchial Tree With Larynx Thumb

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel

Color : White

Control Mode : Switch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS