Laboratory Jaw Crusher for Testing Lab

Laboratory Jaw Crusher for Testing Lab Specification

- Power Consumption

- 3 HP

- Usage

- Laboratory

- Power Supply

- Electric

- Voltage

- 440 Volt (v)

- Product Type

- Laboratory Jaw Crusher

- Material

- Mild Steel

- Size

- 12.5 to 30 mm

- Style

- Floor Mounted

- Weight

- Approx. 120 kg

- Feature

- High strength, easy operation, precise crushing

- Color

- Blue

- RPM

- 400-600 rpm

- Phase

- Three Phase

- Safety Features

- Overload protection

- Maximum Feed Size

- 50 mm

- Application

- Crushing, sample preparation

- Drive Type

- Belt Driven

- Discharge Size Range

- Adjustable, 6-25 mm

- Finish

- Powder Coated

- Jaw Plate Material

- High Manganese Steel

- Crushing Capacity

- 150-250 kg/hr

Laboratory Jaw Crusher for Testing Lab Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Box.

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Africa, Middle East, South America, Asia

- Main Domestic Market

- All India

About Laboratory Jaw Crusher for Testing Lab

Versatile Performance for Specific and General Laboratory Applications

The Laboratory Jaw Crusher is designed for both general and specific uses in testing labs. Its primary usage includes crushing and precise sample preparation of various laboratory samples. Ideal for analyzing materials before further testing or processing, the crusher accommodates different feed sizes and delivers adjustable discharge sizes with each batch. Widely used in industrial labs, research institutions, and production facilities, it is essential for quality control, ensuring accurate and repeatable results in materials testing and analysis.

Sample Policy, Delivery, and Certifications You Can Trust

We offer industry-leading packaging and transport services to ensure your jaw crusher arrives safely and as promised. Our sample policy accommodates inspection and evaluation, so you know exactly what you are receiving. Standard delivery times are prompt, and we provide all necessary certifications for use in esteemed laboratories and industrial settings. Every unit is backed by our commitment to quality assurance and customer satisfaction, making your purchase experience secure and reliable from start to finish.

FAQ's of Laboratory Jaw Crusher for Testing Lab:

Q: How does the overload protection feature benefit the Laboratory Jaw Crusher's operation?

A: The overload protection mechanism safeguards the crusher from potential damages caused by excessive loads, thereby prolonging the equipment's lifespan and ensuring safe, uninterrupted operation in laboratory environments.Q: What is the process for adjusting the discharge size on this laboratory jaw crusher?

A: Adjusting the discharge size is straightforward-users can easily modify settings within a 6-25 mm range, providing flexibility for different sample preparation requirements and specific testing procedures.Q: Where can this jaw crusher be used, and what materials is it suitable for?

A: It's ideal for laboratories, research centers, and industrial testing environments. The crusher is suitable for various hard and soft materials, enabling efficient sample preparation for analysis or further processing.Q: What is the maximum feed size supported by this jaw crusher, and why is it important?

A: The maximum feed size is 50 mm, which allows users to process larger samples efficiently, making the crusher versatile for a range of laboratory applications involving different material types.Q: When can I expect delivery after placing an order, and what packaging is used?

A: Delivery timelines are prompt and communicated at purchase. Each unit is securely packaged using robust materials to prevent damage during transit, leveraging reliable transport services for safe arrival.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pharmacy Equipment Category

GLASS MICROFILTRATION

Price 3000 INR

Minimum Order Quantity : 10 Pieces

Voltage : 220 Volt (v)

Usage : Laboratory

Product Type : Microfilitration

Color : White

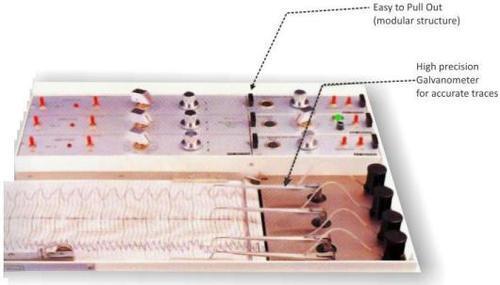

Student Physiograph

Price 3500 INR

Minimum Order Quantity : 10 Units

Voltage : 220 Volt (v)

Usage : For demonstration of physiological experiments in educational institutions

Product Type : Student Physiograph

Color : White

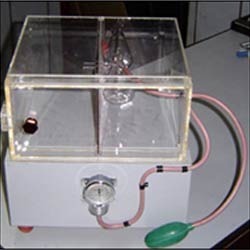

Histamine Chamber

Price 2500 INR

Minimum Order Quantity : 10 Units

Voltage : 220440 Volt (v)

Usage : For allergen and histamine testing in laboratories

Product Type : Histamine Chamber

Color : White

Auto Karl Fischer Titrimeter

Price 4000 INR

Minimum Order Quantity : 1 , , Unit

Voltage : 180210 Volt (v)

Usage : For Fischer

Product Type : Titrimeter

Color : Off White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free